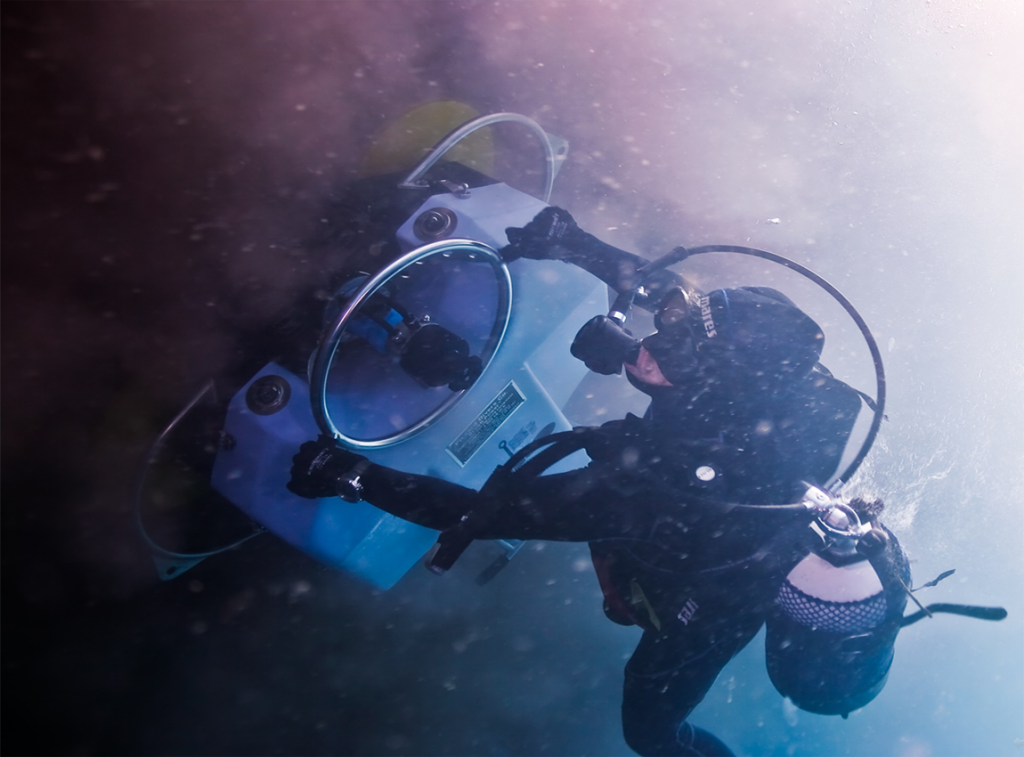

UNDERWATER PAINTING

We have developed an established process for the successful application of underwater coatings to vessels, subsea structures and offshore installations. Prior to the application of protective coatings below the waterline, all marine growth and surface oxidisation is removed by rotary disc preparation, with the steel substrate cleaned to SA 2.5 equivalent. Our developed process known as ‘sacrificial pre-treatment’ then allows applied paint coatings to wet out and bond to the steel surface in water. This process ensures that coatings applied in this way have a much better life expectancy. This service provides a proven waterborne solution for the ongoing protection of assets without the need for costly dry docking or off station periods, using a range of specialist materials including anti-corrosives, antifouling, fillers and adhesives.

Typical underwater applications include:

Re-preservation of detached coatings arising from mechanical damage, shell plate repairs or anchor chaffing

Application of protective coatings to jetty structures/offshore installations

Application of coatings to vessel block areas inaccessible whilst in dry dock

Re-preservation of subsea coatings arising from internal welding repairs

Re-instate hydrodynamic profile (adjacent to hull penetrations/transducers)

USE OF ADHESIVES UNDERWATER

We are also able to provide and apply adhesives suitable for bonding a wide selection of materials underwater for both naval and commercial customers. BPM products typically produce underwater tensile and shear joint strengths in excess of 15Mpa (+150kg/cm²)

Typical underwater applications we offer include:

application of sensor/monitoring equipment